Diesel Repair is a comprehensive suite of maintenance and restoration services tailored for diesel-powered trucks, vans, and SUVs in Yukon, OK. The initial focus is on engine health, covering everything from routine oil changes to complete overhauls of Power Stroke, Duramax, or Cummins powerplants. Beyond engines, specialized technicians address transmissions, suspensions, and exhaust systems to optimize performance under heavy loads. Preventive schedules and detailed inspections mitigate downtime and extend service life for high-mileage vehicles.

Key offerings and scope

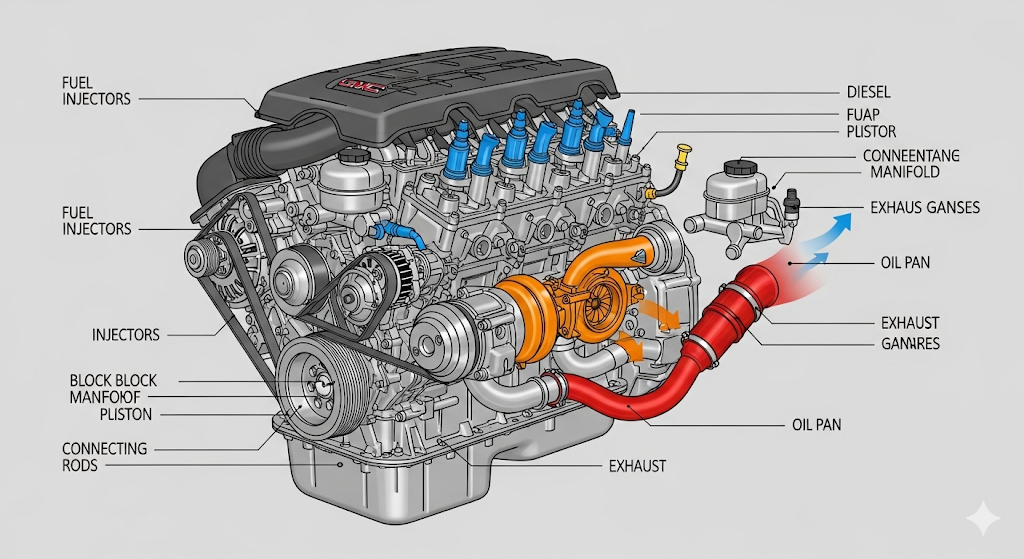

This overview of Yukon Diesel Repair highlights fuel system servicing, turbocharger inspections, and electronic control module (ECM) calibration. High-pressure fuel pumps, injector testing, and particulate filter cleaning ensure emissions compliance and peak efficiency. Drivetrain evaluations and differential adjustments are conducted with OEM-compliant tools. The goal is to deliver reliable, long-term fleet readiness for commercial or personal diesel applications.

Understanding diesel engine diagnostics and local service options

Modern diesel engine diagnostics combine advanced scan tools with hands-on expertise to detect faults in combustion, fuel delivery, and exhaust aftertreatment. The diagnostic process typically begins with onboard diagnostic (OBD) code retrieval, followed by smoke testing and pressure measurements. This approach isolates root causes rapidly, helping shops minimize repair cycles. Proactive troubleshooting prevents minor leaks or electrical glitches from escalating into costly failures.

Integrating local repair networks

Many owners rely on auto repair yukon ok specialists for quick fault assessment and transparent cost estimates. These local service centers maintain factory-level scanners capable of reading manufacturer-specific codes and live data streams. Technicians often cross-reference technical service bulletins to address known issues on models spanning multiple generations. A robust support network of parts suppliers and towing services ensures expedient turnaround.

Preventive maintenance strategies for diesel vehicles

Scheduled maintenance is the backbone of reliable diesel performance, with oil and filter changes recommended every 5,000 to 7,500 miles based on driving conditions. Coolant system flushes, differential oil swaps, and transmission fluid exchanges help avert metal fatigue and component wear. Air and fuel filters are replaced at regular intervals to prevent abrasive particles from compromising injectors or turbo bearings. Seasonal inspections of belts, hoses, and electrical connections reduce the risk of roadside breakdowns.

Semi-annual inspections and adjustments

In Yukon’s varying climate, technicians perform semi-annual reviews that include torque checks, system pressure readings, and emissions compliance tests. This two-tiered approach addresses both mechanical health and regulatory requirements. OEM-approved lubricants and top-grade diesel additives safeguard against regressive wear. A documented maintenance history enhances resale value and underpins warranty claims.

Common diesel repair issues in Yukon, OK

Diesel engines in fleet or recreational service often exhibit symptoms such as excessive smoke, hard starting, and power loss. Injector nozzle failures, turbocharger shaft play, and clogged diesel particulate filters (DPF) rank among the most frequent root causes. Electrical faults like cracked wiring harnesses or failing glow plugs can compound performance issues. Identifying the precise issue early reduces labor costs and prevents collateral damage to related systems.

Seasonal and mileage-related failures

High-mileage diesel vehicles may develop cylinder compression imbalances, leading to rough idling or misfires under load. Yukon’s sandy terrain accelerates air filter contamination and increases downforce on turbochargers. Cold-start concerns in winter months often trace back to weak batteries or malfunctioning intake heaters. Regular drain-and-refill intervals, coupled with combustion chamber carbon cleaning, help restore full-power operation.

Technology and equipment in modern diesel repair shops

Cutting-edge shops invest in OEM-grade diagnostic scanners, high-resolution borescopes, and computerized alignment racks. These systems enable fast root-cause analysis and precise component fitment for engines, transmissions, and suspension assemblies. Laser alignment tools reduce tire wear and steering drift, while full-flow oil analysis identifies microscopic contaminants before they lead to bearing failure. The combination of specialized hardware and software elevates service accuracy and efficiency.

Diagnostic tool comparison

| Tool Type | Primary Function | Key Advantage |

| OEM Scan Tool | Read manufacturer-specific OBD codes | Deep system access and live parameter streaming |

| Aftermarket Code Reader | Basic error code retrieval | Lower cost, user-friendly interface |

| High-Resolution Borescope | Internal component inspection | Non-invasive visual diagnostics |

| Laser Wheel Aligner | Chassis and suspension calibration | Precision alignment under load |

Yukon Diesel Repair for Fleet Maintenance

Yukon Diesel Repair offers tailored fleet maintenance programs designed to minimize downtime and streamline service intervals. These programs integrate digital vehicle tracking, scheduled inspections, and priority booking for high-use trucks or vans. Comprehensive logs cover all services, from oil changes to transmission flushes, ensuring budget predictability for fleet managers. The proactive approach reduces emergency repairs and overall lifecycle costs.

Fleet service deliverables

Yukon Diesel Repair documents each maintenance cycle with time-stamped reports and repair recommendations. Fuel economy analyses help fleet operators identify idling patterns or driver behaviors that increase consumption. Coordinated parts logistics and bulk-order discounts optimize operating budgets. Emergency roadside assistance partnerships ensure disabled units can be quickly towed for shop-side repairs.

Role of ASE-certified technicians in ensuring quality service

ASE-certified technicians bring industry-recognized expertise in engine repair, electrical systems, and heavy vehicle maintenance. Certification requires passing rigorous exams and demonstrating hands-on proficiency with diesel platforms. Technicians maintain continuing education credits to stay current with evolving diesel technologies and emissions standards. Their training ensures that each repair adheres to factory specifications and safety protocols.

Technician qualifications and training

Heavy-duty diesel repair demands specialized skills in fuel injection systems, turbocharger diagnostics, and exhaust aftertreatment calibration. ASE-certified technicians undergo annual recertification, covering advanced topics such as selective catalytic reduction (SCR) and diesel exhaust fluid (DEF) management. Workshops with OEM engineers provide direct insights into recurring field issues. This expertise translates into reduced warranty claims and higher customer satisfaction.

Locating reliable local diesel service providers

Owners seeking dependable service should vet shops based on reputation, warranty offerings, and turnaround times. Online reviews and industry referrals often highlight shops that consistently meet schedule commitments and transparent pricing. A professional waiting area, real-time repair tracking, and direct technician consultations are hallmarks of a customer-centric operation. These factors help ensure peace of mind during complex engine overhauls.

Community-trusted service example

Many residents of Yukon trust facilities such as Yukon OK Express Auto Care for their combination of same-day diagnostics and extended repair warranties. These centers maintain OEM parts inventory and coordinate with regional manufacturers for quick part sourcing. Mobile technicians also offer on-site inspections for fleet or agricultural equipment. Transparent communication channels allow clients to authorize repairs without surprises.

Choosing the right diesel repair shop in Yukon, OK

When selecting a repair facility, decision-makers should evaluate certifications, equipment, and customer support services. A well-equipped shop maintains up-to-date scanning tools, alignment racks, and high-capacity lifts. Clear service agreements outlining labor rates, parts warranties, and diagnostic fees prevent billing disputes. Shops that offer courtesy shuttle services or rental truck coordination add operational convenience for clients.

Evaluating shop credentials

Key credentials include ASE Master Technician status, manufacturer-specific training programs, and affiliations with professional trade associations. Insurance-backed warranties on labor and parts coverage signify confidence in workmanship. Transparent online portals showing repair progress increase engagement and reduce client phone calls. These elements collectively elevate the customer experience and foster long-term relationships.

Customer testimonials and service guarantees

Reviews from local commercial operators and individual owners shed light on real-world shop performance. Consistent five-star feedback often correlates with accurate diagnostics, fair pricing, and on-time delivery. Service guarantees—such as money-back commitments on initial inspections—reflect a shop’s dedication to quality. Warranty extensions on rebuilt engines or transmissions further demonstrate confidence in technical capabilities.

Building trust through transparency

Lead technicians who walk clients through diagnostic findings promote informed decisions. Clear breakdowns of repair scopes, parts origins, and labor factors minimize miscommunication. Detailed service reports document before-and-after performance metrics, such as horsepower restoration or improved fuel economy. This transparency underpins positive word-of-mouth referrals and repeat business.

Comparing OEM and aftermarket diesel parts

The choice between OEM and aftermarket components impacts performance, longevity, and cost. OEM parts deliver direct manufacturer fitment and come backed by factory warranties. Aftermarket equivalents may offer price advantages but can vary in material quality and precision tolerances. Reputable shops test aftermarket injectors and turbochargers against OEM benchmarks to ensure reliable operation.

Parts selection guidelines

Engine rebuilds often favor OEM crankshafts, camshafts, and cylinder heads for guaranteed tolerances. Fuel system rebuild kits from approved suppliers maintain pressure specifications and spray patterns. Aftermarket gaskets and seals from vetted brands are also used for non-critical applications. Documentation of parts sources enhances traceability for future warranty claims.

Cost factors in diesel repairs

Repair costs vary based on labor rates, parts pricing, and repair complexity. Simple maintenance tasks like oil changes and filter swaps usually run under $300, while injector replacements or turbocharger rebuilds can exceed $1,200. Diagnostic fees often cover initial code retrieval and inspection, typically credited toward repair labor if services proceed. Fleet accounts may negotiate volume discounts for recurring maintenance.

| Repair Category | Typical Cost Range |

| Routine Maintenance | $150 – $350 |

| Injector Testing & Repair | $400 – $1,200 |

| Turbocharger Service | $800 – $1,800 |

| Engine Overhaul | $3,000 – $7,500 |

| Transmission Rebuild | $2,500 – $5,000 |

Environmental considerations and eco-friendly diesel service

Diesel repair facilities increasingly adopt eco-conscious practices, including proper disposal of used filters, fluids, and batteries. Water-based parts washers and biodegradable cleaning agents reduce chemical runoff. Shops equipped with advanced DPF regeneration systems minimize particulate waste. Recycling programs for metal and plastic components further lower environmental impact.

Emissions compliance protocols

Strict adherence to EPA and Oklahoma DEQ regulations mandates accurate DEF handling and NoX reduction verification. Technicians perform on-road emissions tests and compare results against manufacturer thresholds. Recordkeeping ensures traceable compliance documentation for fleet audits. Ongoing staff training addresses evolving regulations and emerging eco-friendly technologies.

Innovations shaping the future of diesel repair

Digital twins, augmented reality (AR) repair guides, and remote diagnostic platforms are reshaping service delivery. AR-enabled goggles overlay wiring diagrams and torque specs directly onto engine components, reducing training time. Cloud-based telemetry systems continuously monitor engine health and predict failures before symptoms appear. These innovations promise faster turnarounds and lower lifecycle operating costs.

Predictive maintenance and IoT

Connected sensors relay real-time data on oil quality, coolant temperature, and turbo boost pressure. Machine-learning models analyze trends to forecast potential faults. Shops can schedule interventions during planned downtime, avoiding emergency shop visits. The integration of IoT (Internet of Things) platforms enhances both commercial fleet management and individual ownership experiences.

How to get started with the right diesel repair shop

Prospective clients should begin by requesting detailed service estimates and shop tours to assess equipment and workflow. A transparent intake process includes a written service agreement outlining labor rates, parts markups, and warranty terms. Establishing clear communication channels ensures that any scope changes receive prompt approval. Follow-up inspections and post-repair performance checks verify service quality.

Next steps and contact initiation

After narrowing down options, owners are encouraged to contact us directly to schedule a preliminary diagnostic appointment. Shops offering courtesy loaner vehicles or shuttle service alleviate logistical concerns. Confirming workshop availability and turnaround expectations upfront prevents scheduling conflicts. This structured approach lays the groundwork for a reliable, long-term service relationship.

Conclusion

Yukon Diesel Repair stands as the definitive resource for anyone seeking professional diesel maintenance and restoration services in Yukon, OK. The combination of advanced diagnostics, preventive maintenance strategies, and certified expertise delivers unmatched vehicle reliability and performance. Fleet operators and individual owners alike benefit from transparent pricing, eco-friendly practices, and cutting-edge repair technologies. For top-tier diesel services backed by industry veterans, Ranchwood Auto Works remains the trusted choice.

Frequently Asked Questions about Yukon Diesel Repair

How often should a diesel vehicle receive a comprehensive inspection?

A comprehensive inspection is recommended every 5,000 to 7,500 miles or biannually, whichever comes first. This schedule aligns with manufacturer guidelines and ensures timely replacement of oil, filters, and wear-sensitive components. Early detection of potential issues prevents more expensive repairs down the line. Seasonal climate changes also warrant additional checks before extreme winter or summer conditions.

What role do ASE-certified technicians play in diesel engine maintenance?

ASE-certified technicians have demonstrated expertise in diesel repair through standardized exams and hands-on experience. They stay current with the latest emissions regulations, fuel system technologies, and OEM specifications. Their training minimizes diagnostic errors and ensures all repairs meet factory tolerances. Clients benefit from reduced rework rates and longer component lifespans.

Can a particulate filter be cleaned instead of replaced?

In many cases, diesel particulate filters (DPF) can be restored through controlled regeneration processes that burn off trapped soot and ash. High-temperature oven or on-vehicle injection methods address blockage without compromising filter integrity. Shops monitor back-pressure readings to confirm effective cleaning before reinstallation. Replacement is reserved for filters with irreparable damage or substrate failure.

What diagnostics tools are used to identify turbocharger issues?

Technicians employ OEM scan tools to monitor boost pressures, actuator positions, and turbine speeds in real time. Smoke testers reveal external leaks, while borescopes inspect internal turbine and compressor wheel conditions. Vibration analysis and shaft spin-down tests detect bearing wear or imbalance. These combined methods ensure accurate turbocharger assessments and effective repair plans.

Are warranty provisions available on diesel repair work?

Most reputable shops offer labor and parts warranties ranging from 6 months to 24 months or 12,000 to 24,000 miles, depending on repair complexity. Extended warranties may cover major engine overhauls or transmission rebuilds. Warranty terms are documented in the service agreement, specifying coverage limits and any required service intervals. Adhering to recommended maintenance schedules keeps warranties in force.