Yukon Diesel Repair specialists agree that every diesel-driven GMC Yukon requires a structured maintenance routine to avoid unexpected failures. Diesel engines operate under higher compression ratios and extreme torque loads, making routine diesel service indispensable for performance and safety. A comprehensive checklist helps drivers verify critical systems—fuel filter condition, coolant system integrity, and brake inspection—before each journey. Consistent preventive care not only safeguards reliability but also preserves resale value for high-mileage Yukon SUVs.

What should a routine diesel service for Yukon vehicles include?

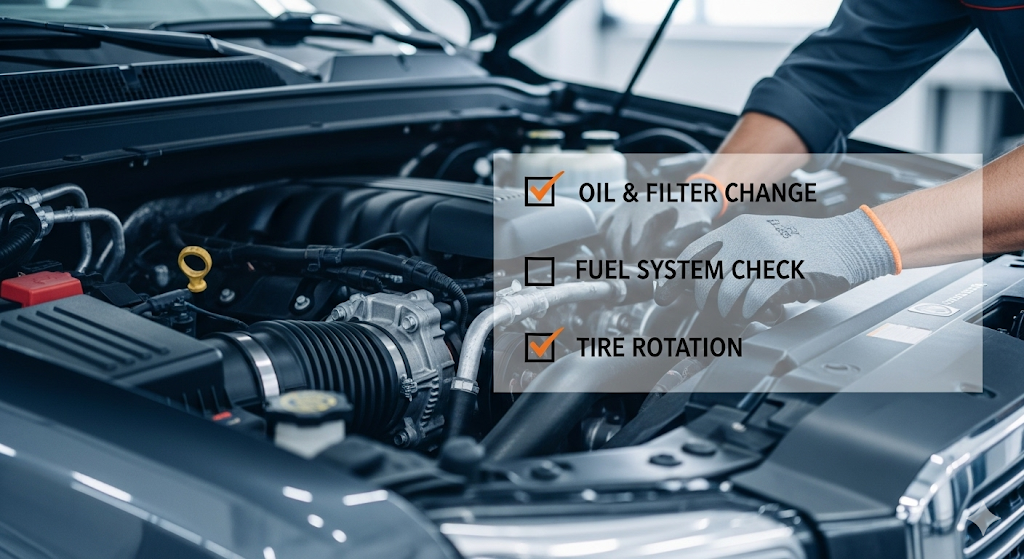

A full maintenance schedule for diesel-powered Yukons begins with an oil and filter swap. High-quality diesel engine oil combats soot buildup, while a filter replacement guide ensures the fuel filter and air filter are changed at manufacturer-recommended intervals. Next, inspecting the coolant system prevents engine overheating in both subzero mornings and summer haul runs. Safety inspections follow, encompassing brake inspection, tire pressure checks, and verifying lights and warning indicators. Finally, a quick scan of belts, hoses, and electrical connectors rounds out a professional-grade service.

In mid-service consultations, many drivers discover that scheduled maintenance uncovers underlying issues before they escalate. Technicians often use diagnostic scanners to read error codes, confirming that sensors for emission controls and fuel injection systems remain within tolerance. Addressing minor leaks or worn serpentine belts during these appointments saves hours of roadside downtime. A proactive approach blends technical precision with on-the-road practicality, keeping Yukons on schedule and on the move.

A trusted reference during any service is the digital Guide to Yukon Diesel Repair. It offers step-by-step instructions, recommended interval data, and torque specifications for drain plugs and filter housings. Accessing this guide assists mechanics and DIY enthusiasts alike in maintaining factory tolerances. Ultimately, a well-executed maintenance session translates into reliable starts, smooth acceleration, and consistent towing power for Yukon owners navigating rural or urban routes.

How often should Yukon drivers follow a maintenance schedule?

An effective maintenance schedule hinges on mileage milestones and operating conditions. For most Yukon models towing heavy loads or traversing off-road trails, the intervals accelerate. Below is a typical guideline:

| Mileage Interval | Key Tasks |

| Every 5,000 miles | Oil & filter change, tire rotation, fluid level check |

| Every 15,000 miles | Replace air filter, inspect cabin filter, check belts |

| Every 30,000 miles | Fuel filter service, coolant flush, brake inspection |

| Every 60,000 miles | Transmission service, spark plug evaluation |

Drivers in dusty environments may replace fuel and air filters more frequently, with shorter oil-change intervals for severe-service specifications. Similarly, cold-climate regions benefit from more frequent coolant tests and battery load checks. Adhering to these intervals prevents sludge accumulation and maintains lubrication pathways essential for diesel longevity.

Routine record-keeping cements accountability. Logging each service appointment, odometer reading, and parts used creates a clear history for future buyers or warranty claims. Many professional shops provide digital logs to track filter replacements, fluid top-ups, and any corrected fault codes. This administrative diligence complements hands-on expertise, reinforcing every aspect of preventative care.

In peak seasons—such as winter freeze-thaw cycles—additional inspections of water-separator drains and glow plug operation ensure reliable cold starts. A few extra minutes at each checkpoint can mean the difference between a smooth departure and a lost day of productivity.

In local searches, drivers often look for auto repair yukon ok when vetting service providers built on reputation and expertise. Skilled technicians at these facilities align each service with both manufacturer standards and regional driving demands.

When is a filter replacement guide essential for diesel engines?

Diesel drivers know that clogged filters throttle performance faster than any other component failure. A precise filter replacement guide directs the sequence: relieve filter canister pressure, drain accumulated water from the fuel/water separator, then swap the canister or media element. For fuel filters, changing at 15,000 to 30,000-mile intervals helps prevent clogged injectors and uneven engine idling. Air filters follow a similar path—removing dust, soot, and debris to preserve turbocharger and intercooler health.

Maintaining the brake inspection protocol in tandem with filter service maximizes safety. When a filter element is removed, technicians often extend the inspection to hoses, clamps, and sensor attachments. Overlooking a loose clamp or cracked hose can introduce contaminants, negating the effort spent installing a fresh filter cartridge.

Filter media technology has advanced, with multilayer cellulose and synthetic blends capturing sub-micron particles. Choosing OEM-spec or high-grade aftermarket parts ensures designed fluid flow rates and bypass valve calibration. Deviations in filter geometry can introduce pressure fluctuations, potentially triggering the engine-control module to log diagnostic trouble codes.

For Yukon owners needing rapid, professional filter services, Yukon OK Express Auto Care combines timed appointments with genuine filter stocks. Their express lanes handle routine filter swaps and fluid checks within a single technician rotation.

Yukon Diesel Repair: Enhancing engine performance

Yukon Diesel Repair expertise begins the moment engine oil is drained. A clean oil fill reduces friction across crankshaft bearings and piston rings, critical for high-compression diesel engines. Replacing the oil filter immediately afterward prevents old oil from re-entering the system. Next, torqueing the drain plug to factory spec avoids gasket failures while protecting the oil pan threads.

Fuel system integrity is equally paramount. Fresh diesel filters improve injection spray patterns, maintaining combustion efficiency and lowering soot production. A well-maintained fuel/water separator keeps water out of injectors, guarding against corrosion and poor atomization.

Scheduled maintenance of the coolant system safeguards against heat-related damage. Inspecting hoses, thermostat operation, and radiator fins prevents hotspots within the cylinder heads. A coolant flush every 30,000 miles removes mineral deposits and maintains pH balance, protecting aluminum components from corrosion.

Turbocharger health relies on clean intake air and precise oil supply. After filter replacement, allowing the engine to idle briefly under warm-up conditions circulates fresh oil through turbo bearings. This practice minimizes abrasive wear and extends the turbo’s service life, translating into sustained boost pressure and throttle response.

Checking the coolant system

A diligent coolant system check confirms that hoses are free of bulges or cracks and clamps hold hoses securely at fittings. Thermostat operation should open at specified temperature to regulate flow through the radiator. Level and concentration tests reveal whether antifreeze properties remain intact for freeze and boil protection.

Inspecting brake inspection and tire pressure

Brake inspection involves measuring pad thickness, checking caliper operation, and ensuring rotor surfaces are free of scoring. Tire pressure checks optimize rolling resistance and load distribution—vital for towing confidence. Inspecting lug nuts for proper torque prevents wheel loss on highways.

Air filter and fuel filter maintenance

Air filter service removes panel or cartridge elements laden with dust; a new media element restores unrestricted airflow into the turbocharger. Fuel filter swaps follow, with careful disposal of used filters and sealed containers to manage diesel waste. A quick prime procedure prevents air locks in the fuel lines after replacement.

Recognizing Common Diesel Vehicle Issues in Yukon trucks

Older diesels often display telltale symptoms before a major malfunction. Intermittent stalling can indicate a clogged fuel filter, while white smoke on startup signals excess coolant ingestion from a failing head gasket. Unusual knocking noises during acceleration may point to injection timing drift or worn piston skirt edges.

Ignoring these early signs may accelerate component wear across turbochargers, pistons, and bearing journals. By understanding Common Diesel Vehicle Issues, Yukon operators can request diagnostic scans and corrective repairs before downtime escalates costs. Seasonal maintenance checks—especially in harsh winter or dusty summer conditions—help intercept potential failures early.

Engine misfires or rough idling often tie back to injector cleanliness and glow plug performance. Scheduled injector cleaning or replacement maintains spray patterns, improving cold-start combustion. Glow plug testing before fall ensures plug longevity and predictable starts when temperatures dip.

Decoding warning signs: when to seek professional servicing

Failure to heed dashboard warnings—like low oil pressure or high coolant temperature—can lead to catastrophic engine damage. Professional servicing offers in-depth diagnostics using scan tools that can access OEM-level trouble codes. Brake system faults, indicated by dashboard alarms or pedal pulsations, demand immediate attention to maintain stopping power.

An official Guide to Yukon Diesel Repair outlines exact troubleshooting steps and OEM torque specs. Following these procedures ensures repairs align with factory tolerances. Whether it’s turbo boost pressure calibration or EGR valve cleaning, a structured guide streamlines the repair process and guarantees consistency.

Benefits of a proactive maintenance approach

Proactive preventive diesel maintenance extends engine life by thousands of miles. Clean oil passages and unimpeded fuel lines preserve compression ratios and injector performance. Regular coolant system flushes prevent corrosion that can pit cooling jackets and cylinder head surfaces.

From an economic perspective, small investments in filters, fluids, and inspections reduce catastrophic repair bills. Maintaining detailed service records enhances resale value by demonstrating care. A certified service report evidences that a Yukon’s engine never suffered neglect, commanding higher offers in private or dealer trade-in transactions.

DIY vs professional service: making the right choice

Some truck owners prefer a hands-on approach, relying on personal tool kits and service manuals. While DIY saves labor charges, professional shops offer specialized equipment—such as oil flush systems and computerized diagnostics—to ensure thorough inspections.

When a complex repair arises, like turbocharger rebuilds or high-pressure fuel pump replacements, professional expertise minimizes missteps. Certified mechanics follow OEM guidelines, use calibrated torque tools, and dispose of hazardous fluids in compliance with environmental regulations.

For those ready to schedule expert care, contact us at Ranchwood Auto Works to access certified technicians, genuine parts, and transparent service quotes. Their team combines diesel-specific training with dealership-level diagnostic capabilities, ensuring every Yukon receives factory-quality attention.

Conclusion

Preventative care remains the cornerstone of long-term diesel engine health for Yukon drivers. A structured checklist—encompassing oil and filter changes, scheduled inspections of coolant and fuel systems, brake and tire evaluations, and early issue recognition—lays the groundwork for reliable performance. Integrating a professional maintenance schedule and following a trusted filter replacement guide reduces downtime and extends engine life.

Yukon Diesel Repair best practices, paired with periodic checks of the coolant system, fuel injectors, and air filters, ensure that every journey is smooth and efficient. For Wellington-area drivers seeking expert assistance, Ranchwood Auto Works stands ready with skilled technicians, OEM-grade parts, and a commitment to sustaining the powerful heritage of diesel-powered Yukons. Trust Ranchwood Auto Works to keep every Yukon running at peak performance mile after mile.

Frequently Asked Questions

What is the ideal interval for oil changes on a diesel-powered Yukon?

For typical highway driving, every 5,000 miles or six months—whichever comes first—is recommended. Severe-service conditions may warrant a shorter interval of 3,000 miles.

How can I tell if my diesel fuel filter needs replacement?

Signs include difficulty starting, intermittent stalling, and reduced power under load. Water-separator drains may show excessive moisture or debris.

Are air and fuel filter changes necessary at the same mileage?

Not always. Most manufacturers list air-filter replacements at 15,000 to 30,000 miles, while fuel filters may extend to 30,000 to 60,000 miles depending on diesel quality and driving environment.

Can I perform coolant system maintenance at home?

Simple checks—like verifying fluid level and condition—are feasible. However, full coolant flushes and thermostat replacements often require professional tools and safe disposal methods.

What are the risks of skipping preventive maintenance on a diesel engine?

Neglecting maintenance can lead to increased soot buildup, turbocharger wear, injector failures, gasket leaks, and ultimately, costly breakdowns and engine replacements.