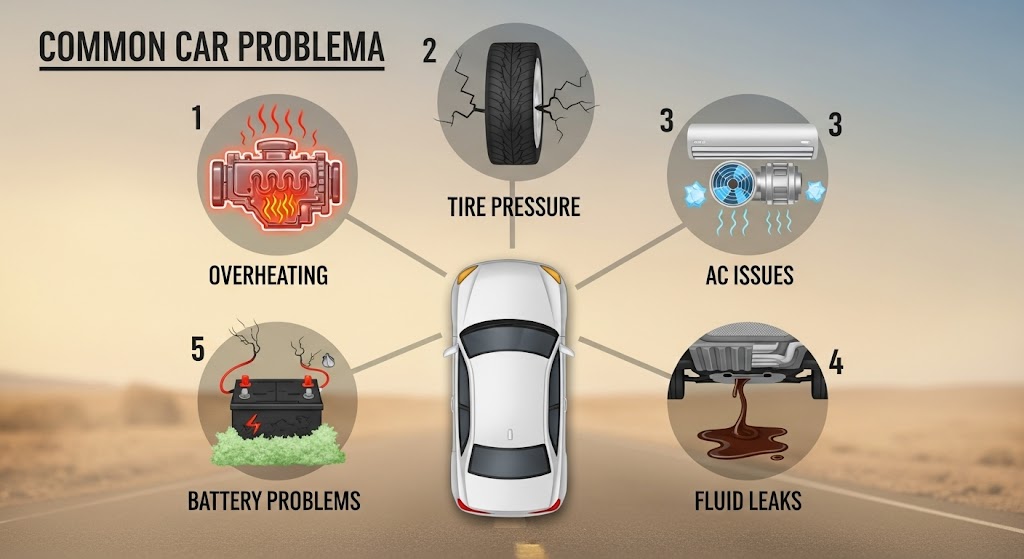

Yukon drivers trust their vehicles to perform reliably on long commutes and weekend adventures alike. Yet even well-maintained SUVs and trucks can develop hidden faults that compromise safety and comfort. In Yukon, Oklahoma, residents rely on the expertise of local mechanics to catch issues early and keep vehicles running smoothly. An Auto Repair Shop in Yukon, OK plays a pivotal role in diagnosing subtle symptoms before they become costly repairs. This guide explores the top five most common car problems that Yukon drivers should watch for, detailing warning signs, underlying causes, and proactive maintenance tips to minimize downtime and repair costs.

What warning signs indicate a Yukon vehicle is in trouble?

Every Yukon driver should learn to recognize the subtle cues that their vehicle needs attention. A dashboard warning light might be the most obvious indicator of trouble, but there are many other signs that foreshadow major repairs.

When the air conditioning suddenly blows warm air in the peak of summer, it’s more than an inconvenience—it can signal a clogged evaporator or a failing compressor. Similarly, erratic oil levels that drop between fill-ups often point to internal engine consumption or seal leaks. Unusual sounds under heavy braking, such as grinding or squeal, usually suggest worn pads or warped rotors. Drivers may also notice a flickering tailgate light at night before a complete bulb failure leads to decreased visibility on the road.

Detecting these symptoms early hinges on regular inspections and listening closely to your vehicle’s normal operating noises. A subtle hissing near the engine bay when idling could indicate a vacuum leak, affecting fuel economy and throttle response. By staying aware of these cues, Yukon motorists can schedule timely diagnostic tests and avoid breakdowns on the highway.

How an Auto Repair Shop in Yukon, OK Can Help Diagnose Common Car Issues

An Auto Repair Shop in Yukon, OK offers the latest OEM-compatible scanners and ASE-certified technicians capable of pinpointing faults accurately. When a Yukon SUV exhibits irregular performance, these professionals use comprehensive auto diagnostics Yukon services to trace the root cause.

A full system scan reveals error codes stored in the engine control unit, guiding technicians to assess components such as oxygen sensors, fuel injectors, or throttle actuators. ASE-certified mechanics inspect belts and hoses visually, check fluid levels with precision, and test electrical circuits for continuity. Their experience with local driving conditions—from dusty backroads to highway commutes—enables tailored maintenance plans that extend the life of your vehicle.

Whether it’s a shadow of smoke from the tailpipe during startup or a gradually softening brake pedal, an expertly staffed repair shop provides clarity and confidence. By combining detailed inspection reports with transparent cost estimates, customers understand the scope of recommended repairs before any work begins.

1. Air Conditioning System Failures

A well-functioning air conditioning system is indispensable in Oklahoma’s hot summers, yet Yukon drivers frequently report cooling issues in SUVs and trucks. An ineffective AC often begins as a weak airflow or lukewarm vent air, eventually progressing to a complete loss of cooling function.

Most commonly, a filthy cabin air filter restricts airflow and forces the system to work harder, leading to reduced cooling capacity. Over time, debris and dust coat the condenser and evaporator coils, impairing heat exchange. Faulty blower motors or deteriorating compressor clutches further degrade performance and may trigger dashboard warning lights associated with the climate control module.

During routine seasonal checkups, technicians recommend cabin filter replacement every 15,000 miles and thorough AC performance tests. A dye-infused refrigerant can quickly reveal leaks in hoses or O-rings, enabling precise repairs before refrigerant loss reaches critical levels. Early intervention prevents compressor burnout and ensures comfortable driving even on the hottest Yukon afternoons.

When localized corrosion affects condenser fins—often from road salt or debris—airflow channels become blocked, causing uneven cooling. Technicians use high-pressure air or specialized cleaning solutions to restore condenser efficiency. In severe cases, condenser replacement may be necessary to maintain system integrity.

Additionally, modern HVAC systems incorporate electronic actuators that regulate airflow distribution. A malfunctioning actuator can trap hot air in certain vents, confusing drivers who struggle to adjust cabin temperature. Experienced mechanics inspect wiring harnesses and test actuator position sensors to guarantee balanced cooling across all vents.

2. Excessive Oil Consumption and Engine Wear

No vehicle is immune to gradual oil consumption, but Yukon drivers often confront unusually rapid oil loss between routine oil changes. Excessive oil consumption manifests as low oil pressure warnings or by requiring engine oil top-offs more frequently than the manufacturer’s recommended intervals.

One primary culprit is worn or damaged piston rings, allowing oil to seep into the combustion chamber and burn alongside fuel. This results in bluish exhaust smoke, reduced engine efficiency, and elevated hydrocarbon emissions. A compression test quickly identifies cylinders with poor ring sealing, guiding targeted ring replacements without overhauling the entire engine.

Another source of oil consumption is deteriorating valve stem seals, which fail to prevent oil from entering the combustion chamber from above. Replacing seals during valve cover gasket service often resolves this issue. In high-mileage Yukons, cracked or warped oil pans and faulty PCV (positive crankcase ventilation) valves also contribute to oil loss and should be inspected during routine maintenance.

Failure to monitor oil levels diligently can exacerbate engine wear, leading to piston scuffing or bearing damage. Yukon motorists should establish a habit of checking oil levels every fuel fill-up and carrying a quart of the specified grade oil in their trunks. Many technicians recommend synthetic blends that withstand higher operating temperatures and maintain consistent viscosity under load.

Periodic engine flush treatments may help remove sludge and varnish buildup, restoring oil pathways in critical components. When scheduled alongside oil changes, this service enhances lubrication and prolongs engine life, especially for vehicles subjected to heavy towing or off-road use frequently encountered by Yukon residents.

3. Tailgate and Brake Light Malfunctions

Properly functioning exterior lights are vital for safety and legal compliance, yet Yukon drivers often discover a burned-out tailgate or brake light only after it fails. In many full-size SUVs, access to tailgate lamps involves maneuvering around interior panels, making bulb or socket replacements a chore best left to professionals.

Corrosion in wiring harness connectors commonly causes intermittent lighting failures, exacerbated by moisture ingress during rainy seasons. Technicians perform continuity tests on circuits and apply dielectric grease to protect contacts. In severe cases, damaged wiring must be spliced or replaced to restore reliable operation.

Brake light switches also warrant inspection whenever brake pedal feel changes or lights flicker under load. A worn switch may fail to activate the rear燭ighting under certain pedal positions, creating hazardous conditions at intersections and prompting traffic violations.

Beyond lamps and sockets, modern vehicles integrate tailgate modules that manage lighting sequences and lock actuation. Software glitches within these modules can disable lights or distort operation. Mechanics with OEM-level scanners verify and update module firmware, ensuring compatibility with vehicle electronic architectures.

In addition to lighting, sensors embedded in tailgate assemblies detect open or closed status. A faulty sensor can trigger warning messages on the instrument cluster and prevent remote key fob functions from operating properly. Diagnosing sensor faults prevents lockout scenarios and restores convenient access to cargo areas.

4. Brake System Wear and Suspension Issues

Yukon drivers covering frequent stop-and-go traffic put heavy demand on their brakes, leading to accelerated wear on pads, rotors, and calipers. Grinding noises upon braking often signal metal-on-metal contact, indicating that pads have worn down to the backing plate.

Routine brake inspections every 10,000 miles help catch pad thickness below safe thresholds before rotor damage escalates. Technicians measure rotor runout and thickness variance, recommending resurfacing or replacement when wear exceeds manufacturer specifications. Caliper guide pins also require periodic lubrication to ensure even pad engagement and prevent uneven brake pad wear.

Suspension components, including struts, control arm bushings, and sway bar links, suffer stress from rough rural roads and gravel driveways common around Yukon homes. Drivers may notice a change in ride comfort, creaking noises when navigating potholes, or wandering steering on the highway.

Shock absorbers and struts should be inspected annually; leaking fluid or pitted bodies indicate imminent failure. Worn bushings lead to deferred steering response and uneven tire wear, reducing handling precision. A qualified shop performs alignment checks after suspension repairs to maintain steering geometry and prolong tire life.

5. Fuel Injector O-Ring Leaks and Smoke From Tailpipe

Fuel injector O-rings seal injectors to the intake manifold, preventing air and fuel leaks. Over time, heat cycles cause these small rubber seals to harden and shrink, leading to vacuum leaks and lean running conditions.

Yukon drivers may notice a rough idle, hesitation on acceleration, or a distinct fuel odor under the hood when an injector O-ring fails. A smoke machine test or injector pull-and-inspect procedure helps locate leaks. Replacing O-rings during routine fuel system cleaning prevents residual debris from compromising seals.

Leaning fuel mixtures can also cause a lean-burn engine light or intermittent engine misfires. Mechanics perform cylinder balance tests, reading misfire counts in each cylinder to confirm injector performance. A comprehensive cleaning of injectors with detergent additives and ultrasonic cleaning restores spray patterns and efficiency.

Excessive black smoke from the tailpipe, on the other hand, signals a rich running condition usually due to faulty oxygen sensors, a clogged air filter, or malfunctioning mass airflow sensors. Regular air filter changes and sensor calibrations, combined with prompt O-ring replacements, maintain optimal combustion and emissions compliance.

| Problem | Warning Signs | Recommended Diagnostic |

| Air Conditioning Failure | Warm airflow, weak blow, AC warning lights | Refrigerant leak test, filter & coil check |

| Excessive Oil Consumption | Low oil, blue smoke, oil top-offs | Compression test, valve seal inspection |

| Tailgate/Brake Light Malfunction | Flickering lights, brake pedal unresponsive | Wiring continuity test, switch replacement |

| Brake & Suspension Wear | Grinding brakes, creaks, pulling steering | Pad thickness, rotor runout, alignment |

| Fuel Injector O-Ring Leaks/Smoke | Rough idle, fuel smell, black smoke | Injector leak test, sensor diagnostics |

The Role of Preventative Maintenance in Yukon, OK

Routine service intervals play a crucial role in catching minor issues before they evolve into major repairs. In Yukon, where temperature extremes and varied road conditions prevail, preventative maintenance schedules must adapt to local driving patterns.

Detailed multi-point inspections include fluid analyses, belt tension checks, and visual brake examinations. Oil changes aligned with manufacturer intervals—often between 5,000 and 7,500 miles—keep engine internals lubricated and free of contaminants. Cooling systems require flushes every 30,000 miles to prevent heater core corrosion and maintain winter heating efficiency.

Tire rotation and wheel alignment service every 6,000 miles extends tread life and ensures even wear across all four tires. Cabin air filters changed seasonally improve HVAC performance, while fuel filters replaced per interval protect injectors from debris. A thorough inspection of wiring harnesses and electrical connectors, especially around the front fascia, prevents the most common lighting and sensor failures.

Conclusion

In conclusion, Yukon drivers who stay alert to warning signs—and partner with a reputable Auto Repair Shop in Yukon, OK—enjoy safer roads and more reliable vehicles. By understanding the top five common car problems, scheduling regular preventative maintenance, and addressing faults swiftly, they avoid costly breakdowns and extend the life of their investments. When it’s time for expert service, don’t hesitate to Contact us at Ranchwood Autoworks, where ASE-certified technicians deliver honest diagnostics and quality repairs. Learn more about our history and commitment to the Yukon community on our About Us page, and experience an automotive repair journey that sets the standard for excellence. At Ranchwood Autoworks, your safety and satisfaction drive us forward every mile.

Frequently Asked Questions

How often should Yukon drivers schedule auto diagnostics?

Yukon motorists should have computerized diagnostics performed at least once a year or immediately when a warning light illuminates. Yearly inspections catch developing faults before they impair performance or safety.

What are the most common car issues Yukon OK residents face?

Drivers in Yukon frequently confront AC cooling failures, oil consumption spikes, brake wear, light malfunctions, and injector seal leaks. Seasonal maintenance tailored to local climates helps mitigate these common problems.

How can one identify warning signs vehicle trouble early?

Subtle cues—such as fluctuating idle speed, increased oil consumption, or inconsistent brake feel—signal emerging issues. Monthly visual inspections and attentive listening during drives improve early detection.

What steps should be taken when noticing a failing tailgate light?

First, inspect the bulb socket and replace the bulb if simple. If the issue persists, test circuit continuity, apply contact grease, and check the tailgate module for fault codes. Professional diagnostics ensure complete repair.

Why is it important to consult an auto diagnostics Yukon specialist?

Specialists use OEM-level tools to read proprietary codes and calibrate sensors accurately. Their expertise in local driving conditions and vehicle models ensures precise fault isolation and cost-effective repairs.